In the manufacturing industry, it’s important to ensure that all industrial equipment is functioning properly at all times. A small defect or outage can quickly create huge financial damage.

That’s where machine maintenance comes into play. Performing regular maintenance tasks as a preventive measure will keep your machines running smoothly.

Often times, challenges occur. In modern production, machinery is quite sophisticated. Finding technicians with in-depth expertise in the necessary maintenance skills can be difficult. Instructions on paper are helpful, but especially in a machine environment, they can get dirty quickly. Even on a tablet in pdf format it can still be a challenge to follow instructions, especially when they’re not precise enough or even outdated.

But there is a solution for these problems: Augmented reality (AR)! It is a technology that shows the real world with additional digital information overlaid onto it. With the help of 3D models, virtual information like objects and directions can be visualized in real life, allowing real-time interaction through any handheld device.

In this brief guide, we will show you how the AR technology can be used to improve machine maintenance, reduce the risk of an outage and increase overall ROI through higher efficiency in your workforce.

What Is Machine Maintenance for Manufacturing?

Machine maintenance is the process of performing regular service on machinery to ensure it continues to work properly. It both involves

- preventive maintenance that occurs prior to any sort of damage (for example cleaning, checking parts for any signs of wear and tear)

- processes that are necessary when a machine breaks down (for example replacing broken parts).

Machine maintenance is usually supported by maintenance software systems that help with the maintenance routine and also save data from maintenance cycles that have been previously carried out by technicians to compare and assess whether it’s necessary to act.

How Does Augmented Reality in Maintenance Work?

There are many modern software solutions and systems available for machine maintenance. One of them is the augmented reality solution that we recommend.

Here is how it works:

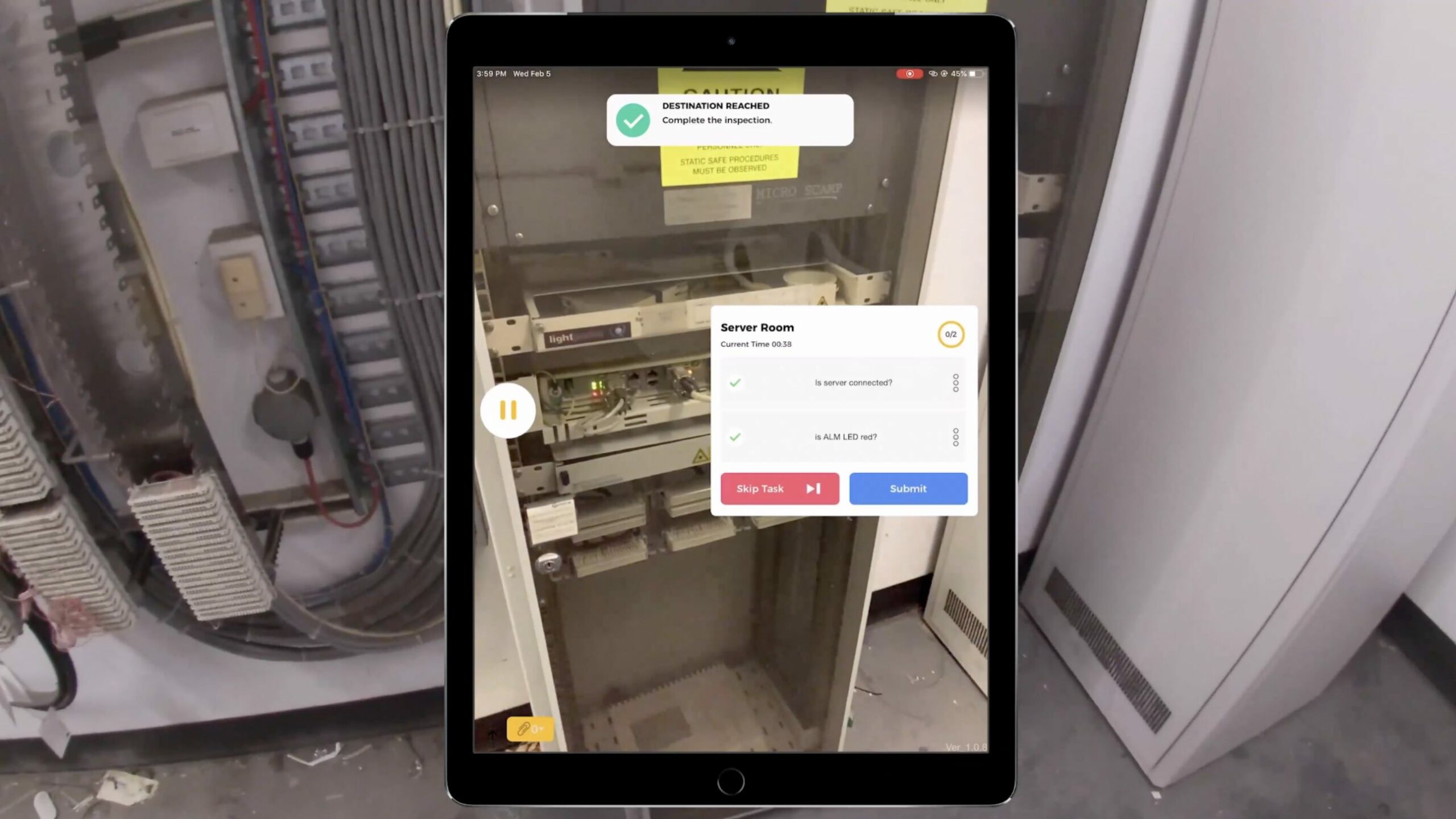

- A mobile device with a camera is used to navigate the worker to the machine that needs to be checked. The system can even be used by technicians that are completely new to the site and environment.

- There are markers placed on the machine or next to it for your device to recognize it and show technical details.

- Relevant digital information like objects, arrows or notes is then displayed on the screen, on top of the “real world” image layer.

- All maintenance checklists and maintenance history are then provided on the device and can be updated accordingly.

What Are the Benefits of Augmented Reality in Machine Maintenance?

Regular preventive maintenance routines will lower defective-rates and therefore are a key measure in any successful manufacturing enterprise looking to increase safety, production volume and overall ROI.

The AR technology provides many benefits for machine maintenance, for example

- Improved Efficiency – An AR system helps to standardize your maintenance workflows. Defects can be highlighted, problems can be identified more quickly and additional information can be provided if necessary. As a result, machine maintenance can be performed more efficiently.

- Easy Wayfinding and Less Errors – AR technology can help manage challenges that occur due to modern production machinery. Technicians can be directed to exact locations and can be guided through the maintenance process by showing them a list of tasks to complete. They can even work on equipment they are unfamiliar with as AR will tell them which part is which, which replacement parts are needed and where they are stored for example. This way, even less experienced workers are able to carry out maintenance and repair tasks with fewer errors.

- Cost Reduction – The simplification of tasks and routes will reduce possible downtime and costs for machine maintenance processes.

Step Up to A New Level of Efficiency With Our Solution “Insider Workforce 4.0” Now

After many years of industry experience we know the needs of manufacturing companies very well. Therefore we do not only offer excellent software/IT solutions but also ensure you don’t have to worry about implementation yourself!

With our AR-Based Insider Workforce 4.0 solution, we provide a full-service solution starting from the initial consultation to implementation of the entire setup on-site right at your facility.

Our specialized partners are distributed all over the world, enabling us to implement the entire technical infrastructure for you. Since there is no hardware-heavy setup needed, the setup will be fast, cost-efficient and easy.

Our solution can be run standalone and also be integrated with any existing system. You can also integrate our various capabilities on top of your existing ERP solution (SAP, Oracle, IBM, etc.), keeping the comfort of your current system with all of the advantages of ours. It works both online (cloud) or offline (on premise).

Book a Free Demo to See Insider Workforce 4.0 in Action!

Find out how you can improve the machine maintenance workflows for your business with our Insider Workforce 4.0 solution. Schedule an appointment for your personal live-demo either per video-conference or on site.

Or reach out using our contact form to receive further information about the system and pricing. We’re looking forward to hearing from you!